Ensuring

compliant

operations

The unified platform

What all equipment needs

Lowering operational costs

Minimising loss

Reducing downtime

Eliminating disruption

About our applications:

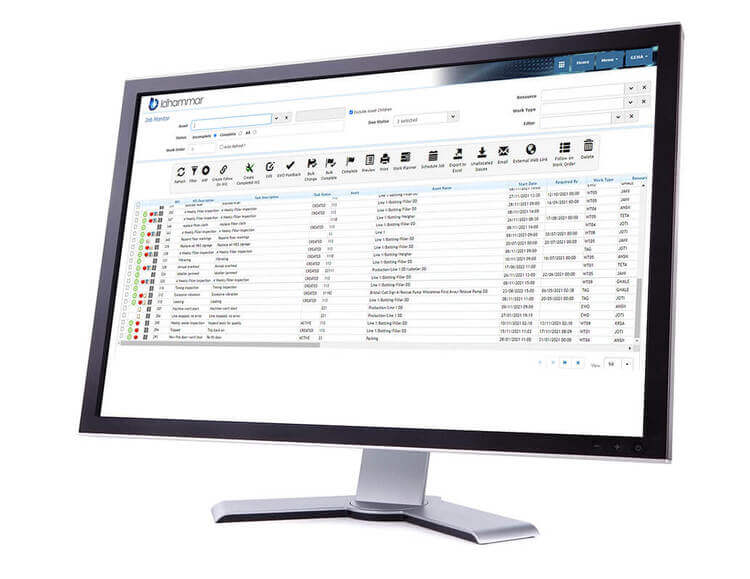

The Idhammar Systems suite

Digital transformation in action

Idhammar Systems use secure SQL data engines for capturing data on the current situation and pinpointing specific elements/events. They help you identify and address root causes and scope for improvement.

Asset management

Condition Tracker

Inventory management

Reporting

Data capture

Core analysis

OEE monitoring

Condition Tracker

Inventory management

Reporting

Data capture

Core ananlysis

OEE monitoring

Asset management

Our customers include…

Unilever

2 Sisters

Chivers Brothers

Aunt Bessies

Aspall

Premier foods

Hovis

We enable you to:

1

Build your toolkit

Our solution suite is modular. You can deploy end-to-end functionality, or simply opt for those aspects of the software you feel your operations will most benefit from.

2

Select your platform

Cloud-based or on-premise. We can help you make the right decision if you are at a transition point from on-prem to cloud.

3

Empower your users

Intelligent and centralised control enables your users to perform routine tasks more efficiently and easily, and deal with problems in their stride.

Idhammar Systems are certified for Quality (ISO 9001) and Information Security (ISO 27001)

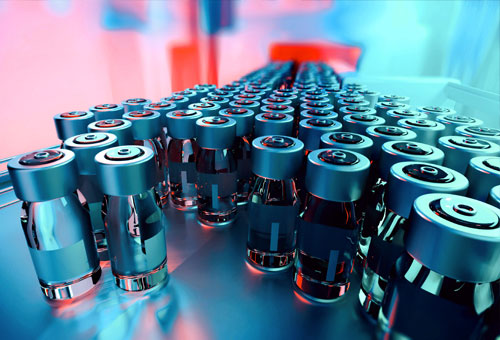

The sectors we serve

An extensive range of machine types on the factory floor requires constant vigilance and diligence.

DRIVE THE CHANGE

With so much to consider, across so many aspects of your operations, managing change may sometimes appear like a complex project. Idhammar Systems’ consultants have direct industry experience and understand your challenges.

We’re here to help you make the best move, in the best way: